At Maverick Industrial Sales, we offer a wide selection of high-quality fluid power & plumbing supplies designed for performance, durability, and efficiency. From industrial cylinders and fittings to precision gauges, our collection of fluid power components supports applications in hydraulic systems, pneumatic machinery, and general industrial use.

These components play a pivotal role in maintaining control, pressure accuracy, and connection integrity across your systems. Understanding the function and value of Industrial Fluid Power Components is key to ensuring smooth operations and maximizing productivity.

Industrial Cylinders

- Hydraulic Cylinders: Built for high force output, perfect for lifting, pushing, and pulling in heavy-duty operations.

- Pneumatic Cylinders: Ideal for rapid and precise motion in automation and assembly lines.

- Linear & Rotary Cylinders: Designed to meet specific motion needs, from straight-line movement to rotational force.

Gauges

We offer a variety of industrial gauges for monitoring pressure, temperature, and flow rate. Whether working with gas lines or fluid systems, the right gauge ensures safety and reliability.

- Pressure Gauges: Available in analog and digital versions—including hydraulic pressure gauges—for accurate system monitoring.

- Temperature Gauges: Prevent overheating or freezing by keeping your system within optimal range.

- Flow Gauges: Help regulate system performance and detect blockages early.

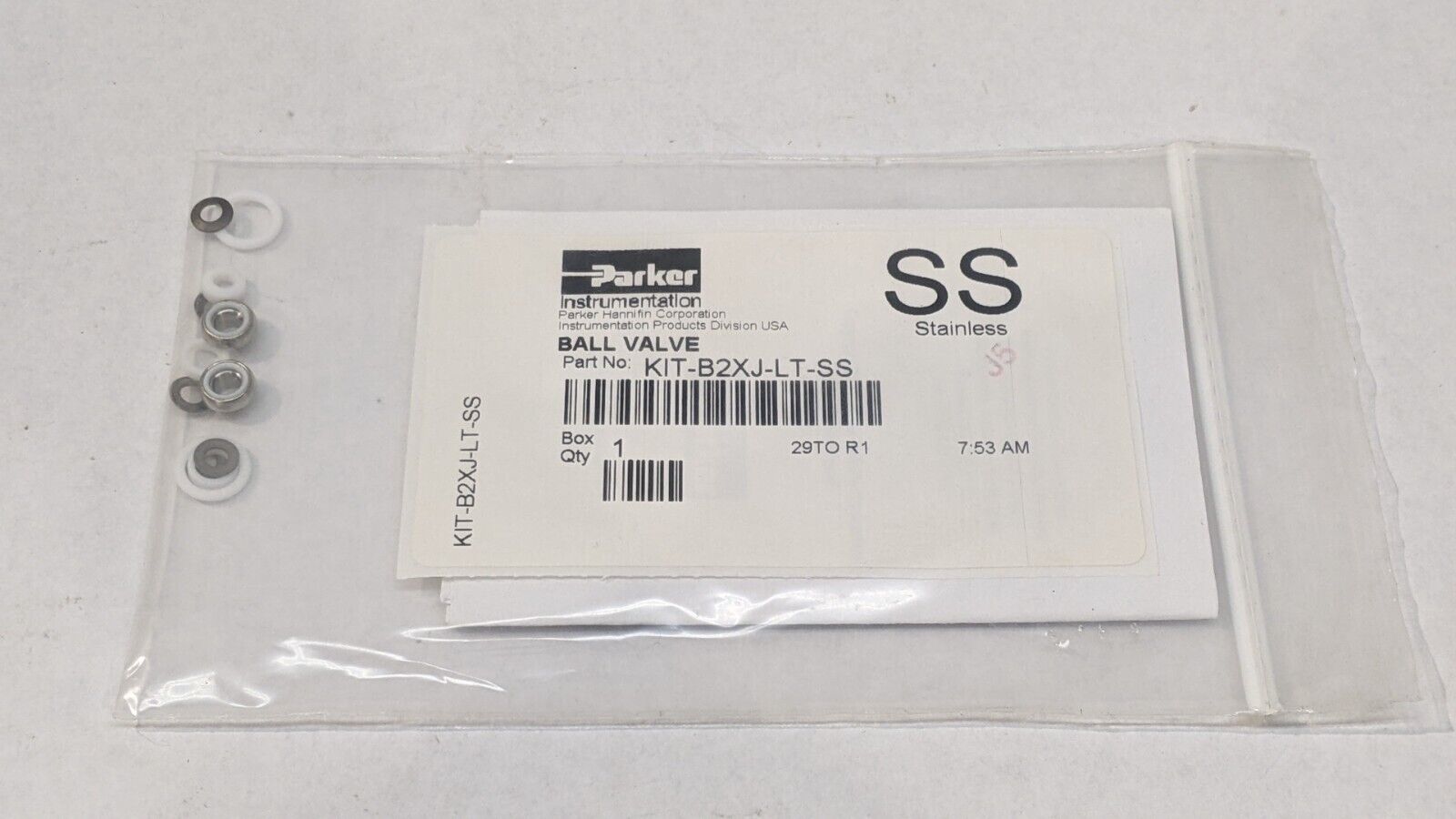

Fittings

Fittings are a crucial part of our fluid power & plumbing supplies, providing reliable connections between your cylinders, hoses, and gauges.

- Threaded Fittings: Secure and easy to install or remove.

- Quick Connectors: Tool-free and fast for enhanced efficiency.

- Flanged Fittings: Engineered for high-pressure environments and robust connections.

We also supply hose tubing options, including clear hose tubing, to support visibility in critical operations.

At Maverick Industrial Sales, we pride ourselves on offering trusted brands and knowledgeable service for all your fluid power & plumbing supplies. Contact us at (269) 932-3156 for help selecting the right components for your system.