Balluff Sensors & Automation Technologies

Maverick Industrial Sales offers you a diverse range of Balluff sensors and technologies that deliver precise, reliable, and real-time data. Our offering includes the following segments:

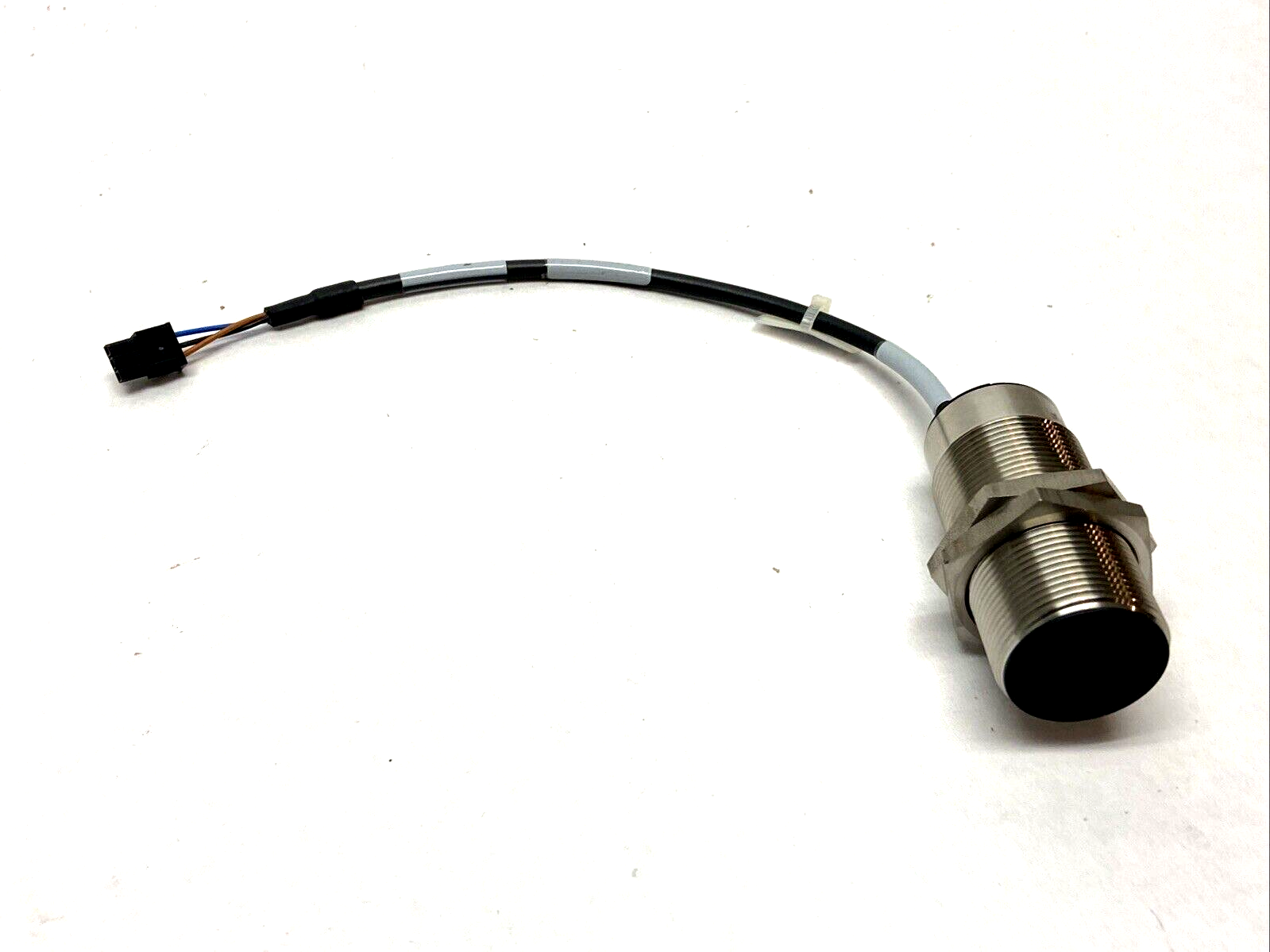

Inductive Sensors: Utilizing electromagnetic fields, inductive sensors detect the presence of metallic objects without physical contact. They are ideal for applications requiring non-contact sensing in harsh or dusty environments.

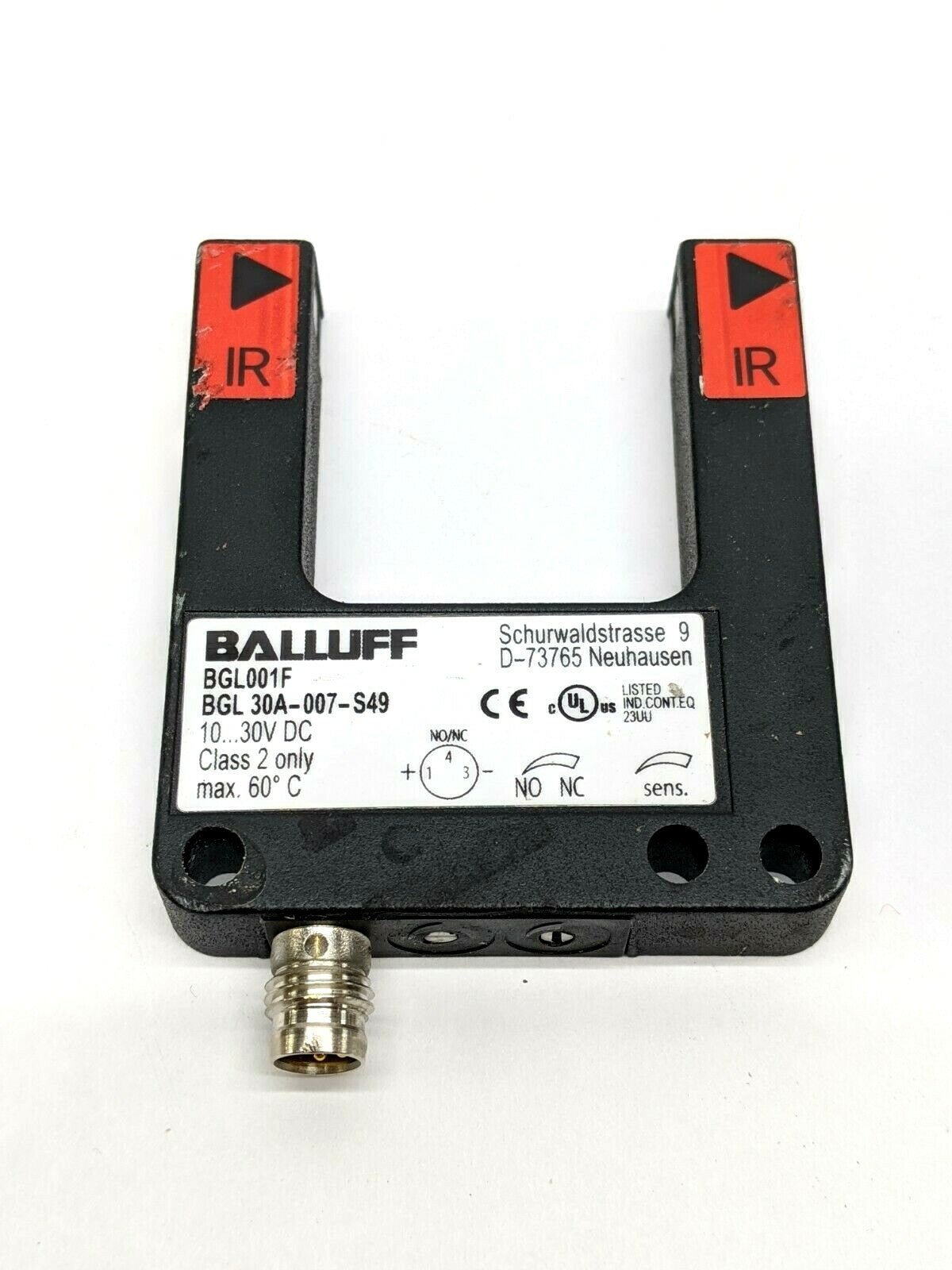

Photoelectric Sensors: Employing light beams to detect objects, photoelectric sensors offer versatility and flexibility across various materials and surfaces. They are commonly used in packaging, material handling, and assembly operations.

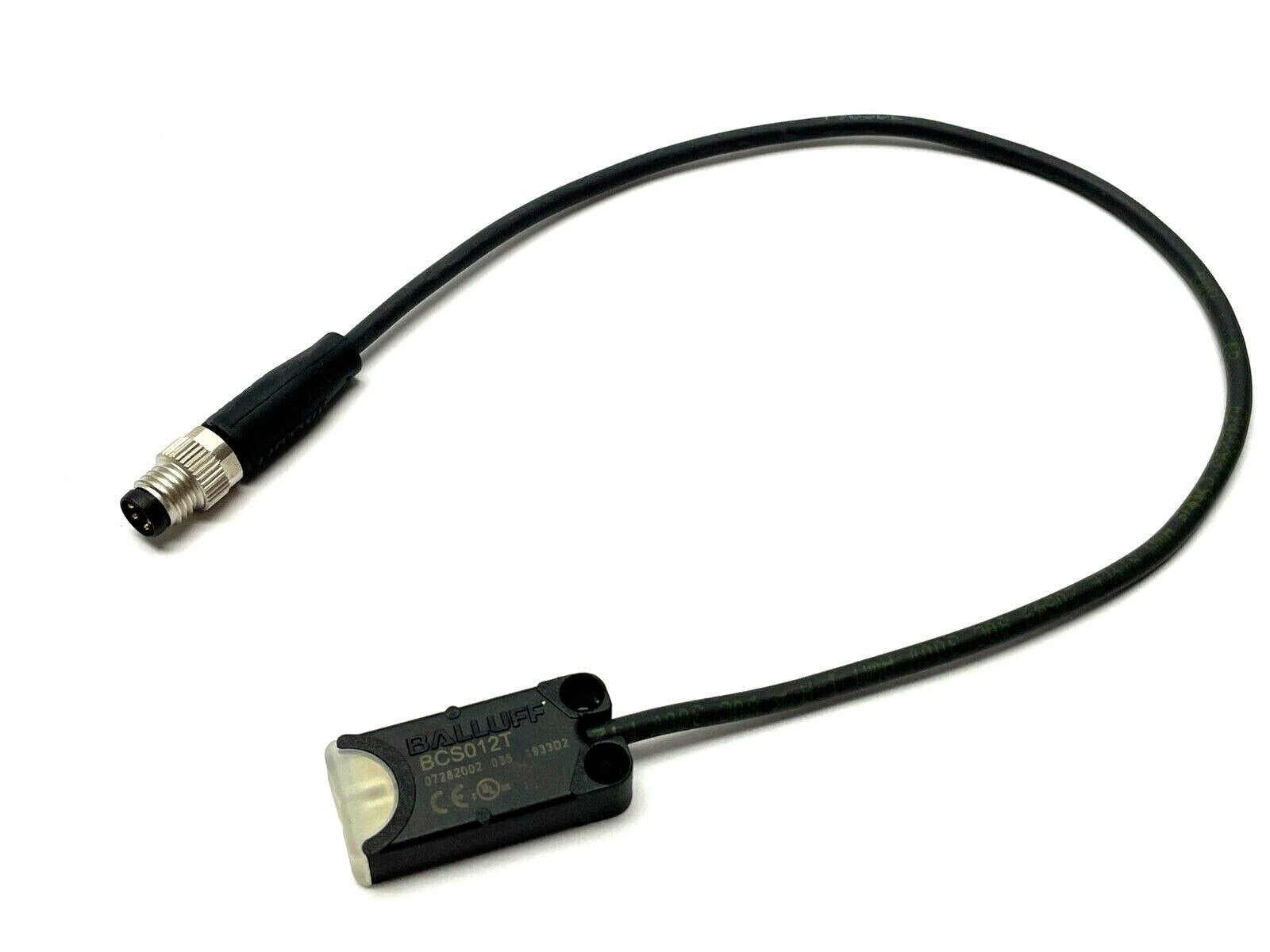

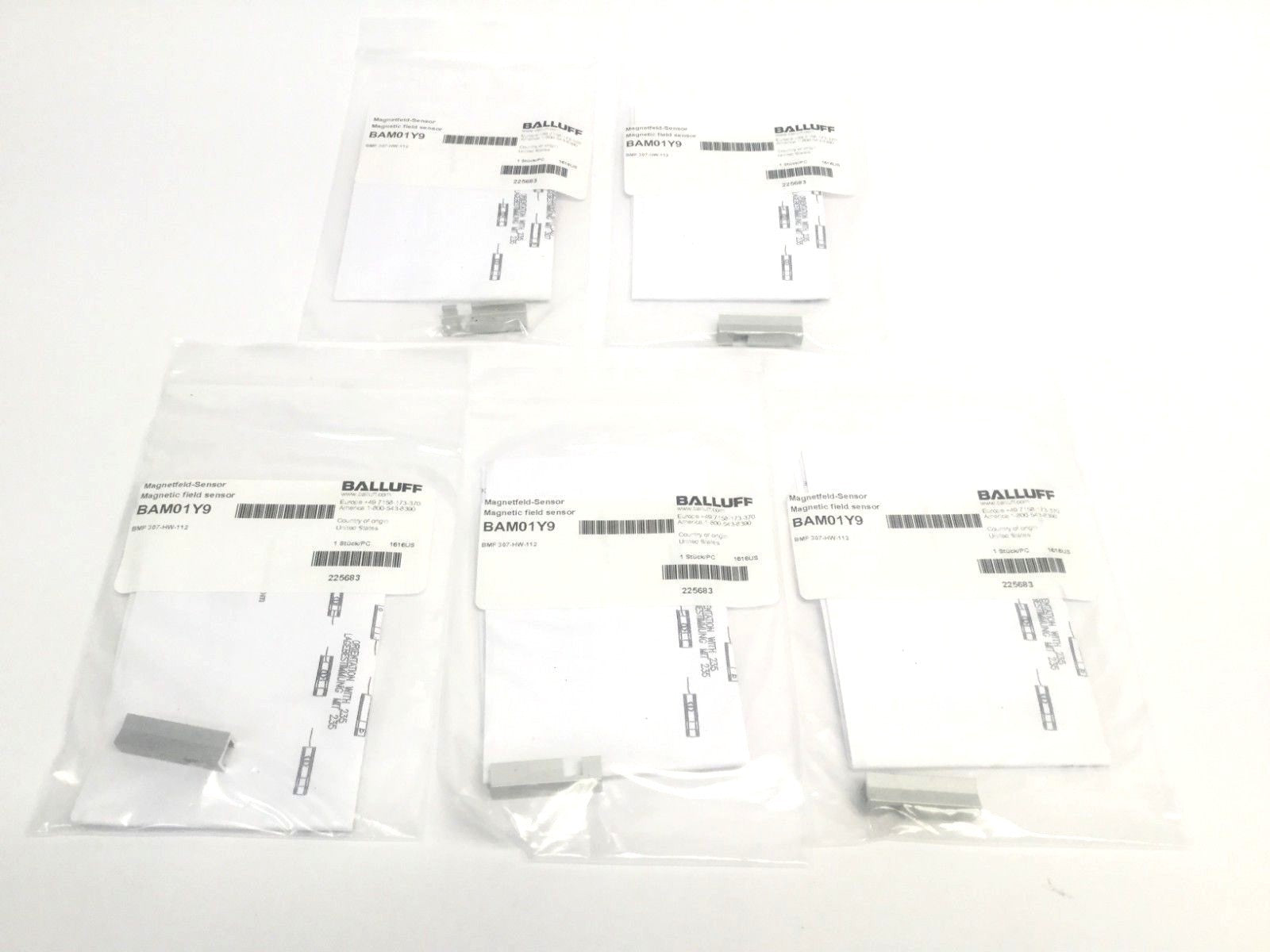

Magnetic Field Sensors: Designed to detect magnetic fields, these sensors are crucial for monitoring position, speed, and direction in applications such as conveyor systems and rotary encoders.

Presence Sensors: Detect the presence or absence of objects in a given area, facilitating precise positioning and automation control.

Measurement Sensors: Provide accurate measurement of distance, level, pressure, and other parameters essential for process optimization and quality assurance.

Identification Systems: Enable reliable identification and tracking of products, components, and assets throughout the production and supply chain.

IO-Link: A standardized communication protocol that enables bidirectional communication between sensors and controllers, providing enhanced diagnostics and configurability.

Ethernet/IP, PROFINET, and EtherCAT: Widely used industrial Ethernet protocols that facilitate high-speed data exchange and seamless integration with PLCs and control systems.

Explore our catalog to find the Balluff sensors you need for smarter industrial automation.